VTdrive Oil Pumping Unit Variable Speed Control Solution

First, Oil Pumping Unit Variable Speed Control Three Kind of Solutions

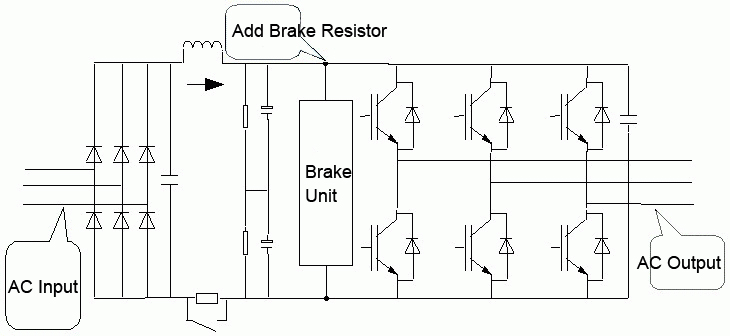

◆ Frequency Inverter plus Brake Unit control

As shown in the following figure: Adding braking resistor and braking unit at both ends of the DC bus of the main circuit of the inverter (this method is high in cost / performance ratio) In the descending section of the motor in the state of power generation. The most closed construction is the descending section, the process is continuous operation, along with the oil consistency, well depth, output regulation reciprocation frequency / MIN, causing the motor into the regenerative state, the excess energy back to the grid, causing the main inverter master Circuit DC bus voltage increases, and the power flow back to the grid without the circuit, you must use resistors to consume locally, which is why we must use the brake unit and brake resistor on the inverter, and my company's products, high-power inverter The device can be built-in brake unit, can achieve the desired control effect.

Figure 1 AC Drive plus Brake Unit

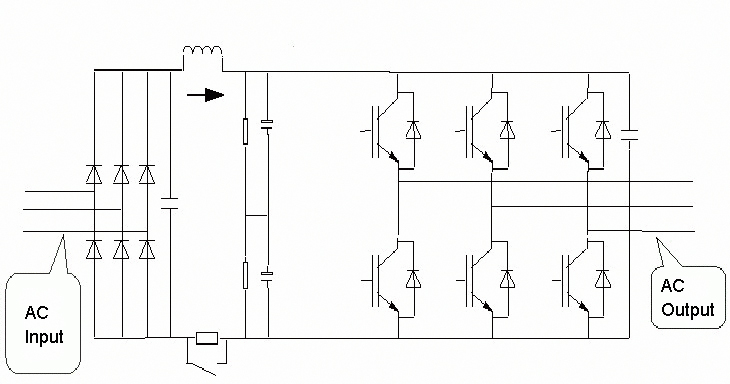

◆ Frequency Inverter plus Regenerative Unit

As shown below, in the inverter DC loop plus feedback device, the state of the motor power generated by the energy, it will be fed back to the grid.

Figure 2 Frequency Inverter plus Regenerative Unit

◆ Automatic intelligent control of Frequency Inverter, without Brake Unit or Regenerative Unit

Under normal circumstances, without the brake unit or the Regenerative Unit, the inverter can automatically adjust operation according to kowtower conditions, the system cost is low, the reliability is higher, the harmonic pollution is reduced, and the operation voltage is more adaptable.

Figure 3

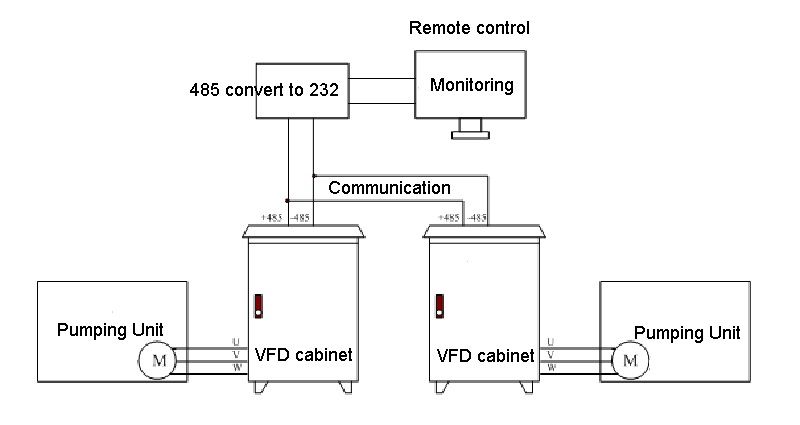

Second, the frequency inverter control system two side control

The following figure: Frequency Control System diagram

Figure 4 Remote control plus On site control

According to the needs of users, each VVVF control cabinet adopts a VT2 series inverter, which is automatically controlled by the open loop speed. The control cabinet has the function of switching between frequency and frequency conversion, , Frequency, stop three gears, easy to operate. When switching to frequency conversion, the inverter runs automatically. The speed adjustment is input from the potentiometer of the control cabinet to the AI1 terminal. At run time, the current current, voltage, power and frequency status can be checked on the panel display. To the host computer control does not require any switching, direct control of inverter start and stop, inverter running status and operating frequency settings, you can also copy the current data included in the document. (see attached)

product advantages:

◆ external equipment with short circuit, lack of phase, overload, imbalance and other comprehensive protection;

◆ highly integrated, high reliability, cost-effective;

◆ Remote, local control, RS-485 communication function;

◆ cabinet, open-air installation;

Third, the AC Drive debugging

Power on the inverter: Press the motor nameplate parameter to set the corresponding P9 group function code, then set P9.15 = 1, press the run key to carry out the parameter self-tuning.

The inverter's function code setting: P0.04 = 1, P0.06 = 1, P5.00 = 02, P5.01 = 50, PA.09 = 1, Pb.15 = 1, Pb.16 = 2.

Return: Back to Previous Level